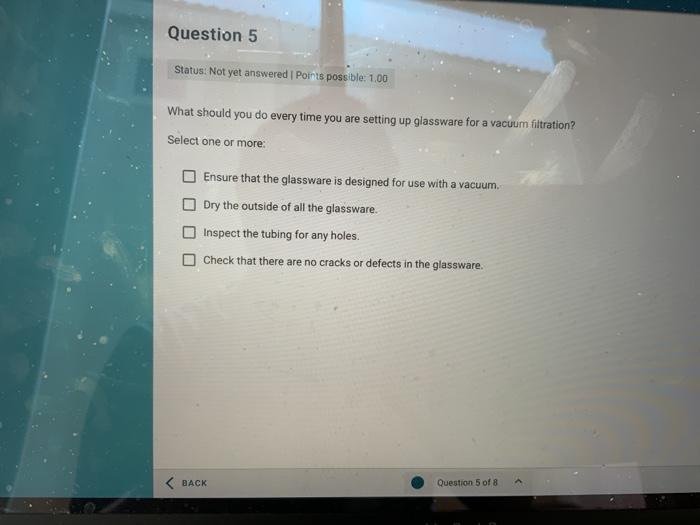

To ensure a successful vacuum filtration process, always remember to thoroughly clean and dry the glassware before setting it up. Proper preparation is key to obtaining accurate results and preventing contamination. What should you do every time you are setting up glassware for a vacuum filtration? Prioritize cleanliness and meticulous care in handling the equipment to achieve optimal filtration outcomes. This simple yet crucial step can make a significant difference in the efficiency and reliability of your experimental setup.

What Should You Do Every Time You Are Setting Up Glassware for a Vacuum Filtration?

The Importance of Proper Glassware Setup

Setting up glassware for a vacuum filtration process is a crucial step in ensuring successful and efficient filtration. Proper setup not only enhances the performance of the filtration process but also helps maintain the integrity of the glassware and prevents accidents or spills. In this article, we will discuss the essential steps you should take every time you are setting up glassware for a vacuum filtration.

Gather All Required Equipment

Before you begin setting up the glassware for vacuum filtration, it is important to gather all the necessary equipment. This includes:

1. Glassware:

Ensure that the glassware you are using is clean and free of any cracks or chips. It is recommended to use borosilicate glassware as it is resistant to thermal shock and chemical corrosion.

2. Filter Paper:

Choose the appropriate filter paper based on the size of the particles you are filtering. Make sure the filter paper fits securely in the filtration apparatus to prevent leaks.

3. Buchner Funnel:

If you are using a Buchner funnel for filtration, ensure it is properly seated and secured in the filtration apparatus. Check for any cracks or damage that may affect the filtration process.

4. Vacuum Pump:

Verify that the vacuum pump is in good working condition and properly connected to the filtration setup. Test the vacuum pump before starting the filtration process to ensure it is functioning correctly.

Assembling the Glassware

1. Set Up the Filtration Apparatus:

Start by assembling the filtration apparatus, including the flask, Buchner funnel, and rubber stopper. Make sure the components fit snugly together to create a secure seal.

2. Prepare the Filter Paper:

Wet the filter paper with a small amount of solvent or the liquid to be filtered. This helps the filter paper adhere to the funnel and prevents small particles from passing through the gaps.

3. Place the Filter Paper in the Funnel:

Carefully place the wetted filter paper in the Buchner funnel, ensuring it lays flat and covers the entire surface area. Press down gently to remove any air bubbles.

4. Secure the Funnel in Place:

Once the filter paper is in position, secure the Buchner funnel in the filtration apparatus, making sure it is properly seated and aligned with the flask below.

Performing the Vacuum Filtration

1. Start the Vacuum Pump:

Turn on the vacuum pump to create the necessary suction for the filtration process. Monitor the pressure gauge to ensure the vacuum level is appropriate for efficient filtration.

2. Pour the Solution to Be Filtered:

Carefully pour the solution to be filtered into the Buchner funnel, allowing it to flow through the filter paper and into the flask below. Avoid overfilling the funnel to prevent spills or clogging.

3. Monitor the Filtration Process:

Watch the progress of the filtration as the liquid passes through the filter paper. You may need to adjust the vacuum level or refill the funnel with solution as needed to maintain a steady flow.

4. Stop the Vacuum Pump:

Once the filtration is complete, turn off the vacuum pump to release the suction. Carefully remove the Buchner funnel from the apparatus and dispose of the filter paper and residue according to proper protocol.

Cleaning and Maintenance

After completing the vacuum filtration process, it is essential to clean and maintain the glassware for future use. Follow these steps to ensure the glassware remains in good condition:

1. Rinse with Solvent:

Rinse the glassware with an appropriate solvent to remove any residue or particles that may have accumulated during the filtration. Use a brush or sponge to clean hard-to-reach areas.

2. Dry Thoroughly:

Allow the glassware to air dry completely before storing it away. Inspect the glassware for any signs of damage or wear and replace any components that are cracked or compromised.

3. Store Properly:

Store the glassware in a dry and secure location to prevent breakage or contamination. Keep the components of the filtration apparatus together to ensure they are ready for the next use.

By following these steps every time you set up glassware for a vacuum filtration, you can ensure a smooth and successful filtration process while prolonging the life of your glassware. Proper setup and maintenance are essential for achieving accurate and reliable results in your laboratory work.

2 Vacuum Filtration

Frequently Asked Questions

What are some important steps to take when setting up glassware for a vacuum filtration process?

When setting up glassware for a vacuum filtration, it is crucial to ensure that all components are clean and free from any contaminants. Begin by assembling the filtration apparatus in the correct order, which typically involves connecting the Buchner funnel to the filtration flask using a rubber stopper. Make sure the filter paper is properly placed in the funnel to prevent any leakage during the filtration process.

How should one secure the connections between the glassware components during vacuum filtration setup?

To prevent any air leaks and ensure efficient filtration, it is essential to securely fasten all connections between the glassware components. Tighten the rubber stopper connecting the Buchner funnel to the filtration flask to create an airtight seal. Additionally, check that any hose connections leading to the vacuum source are properly attached and free from any defects that could compromise the vacuum pressure.

What precautions should be taken when handling the glassware during the setup for vacuum filtration?

When handling glassware for vacuum filtration, it is important to exercise caution to avoid breakage or mishaps. Always use proper protective equipment such as gloves and safety goggles to prevent any injuries. Handle the glassware with care and avoid applying excessive force or pressure when assembling the components to prevent accidental damage or breakage.

Final Thoughts

When setting up glassware for a vacuum filtration, always ensure tight connections to prevent leaks. Use the correct filter size and paper type for efficient filtration. Lubricate the ground glass joints with a thin layer of vacuum grease to create a proper seal. Lastly, confirm that all equipment is assembled correctly before applying the vacuum pressure. Remember, attention to these details is crucial every time you are setting up glassware for a vacuum filtration.