A slip sheet in printing is a versatile tool that plays a crucial role in the printing process. It’s a simple yet effective solution to prevent ink from transferring onto the next sheet. By placing a slip sheet between pages, you ensure crisp, clean prints every time. This small addition can make a significant difference in the quality of your printed materials. Let’s delve deeper into the world of slip sheets in printing and uncover their importance in achieving flawless results.

What is a Slip Sheet in Printing

Printing is a fascinating process that involves various components working together to create beautiful designs on paper. One crucial element of the printing process that is often overlooked is the slip sheet. If you’ve ever wondered what a slip sheet is in printing and why it is important, this article will provide you with all the information you need to know.

The Basics of Printing

Before diving into the specifics of slip sheets, let’s first understand the basics of printing. Printing is the process of reproducing text and images using ink on paper or other materials. It is a widely used method for creating various products such as books, posters, labels, and packaging.

Printing can be done using different techniques, including digital printing, offset printing, and flexography. Each printing method has its unique characteristics and applications, but they all involve transferring ink onto a substrate to create the final printed product.

Introducing the Slip Sheet

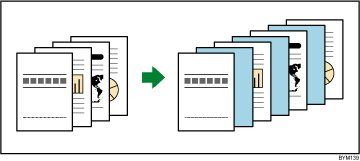

Now, let’s get to the main topic of discussion – the slip sheet. A slip sheet, also known as a separator sheet or interleaf, is a thin, flat sheet of paper or cardboard that is placed between printed materials to protect them and facilitate handling during the printing process.

When multiple sheets of paper are stacked together for printing, there is a risk of the ink transferring from one sheet to another, causing smudging and ruining the print quality. This is where slip sheets come in – they act as a barrier between the printed materials, preventing any unwanted ink transfer.

The Role of Slip Sheets in Printing

Slip sheets serve several important functions in the printing process. Let’s explore some of the key roles they play:

1. Ink Protection

One of the primary functions of slip sheets is to protect printed materials from ink transfer. By placing a slip sheet between each printed sheet, printers can ensure that the ink stays where it’s supposed to be, resulting in clean and crisp prints.

2. Smooth Handling

Slip sheets also help in handling the printed materials more smoothly. Since they reduce friction between the sheets, it becomes easier to separate and stack the printed materials without causing any damage or smudging.

3. Prevent Curling

Another benefit of using slip sheets is that they help prevent the printed materials from curling. By providing a flat and stable surface between the sheets, slip sheets reduce the chances of warping or curling, ensuring that the final printed products look professional.

Types of Slip Sheets

There are different types of slip sheets used in printing, each designed for specific purposes. Some common types of slip sheets include:

1. Anti-Static Slip Sheets

Anti-static slip sheets are specially treated to reduce static electricity, which can cause issues during the printing process. These slip sheets are ideal for printing environments where static electricity is a concern.

2. Coated Slip Sheets

Coated slip sheets are coated with a thin layer of material such as wax or silicone to provide a smoother surface for the printed materials. This helps prevent sticking and ensures that the printed sheets can be easily separated without any damage.

3. Moisture-Resistant Slip Sheets

Moisture-resistant slip sheets are designed to protect printed materials from moisture and humidity, which can affect the print quality. These slip sheets are commonly used in environments where moisture levels are high.

In conclusion, slip sheets play a vital role in the printing process by protecting printed materials, facilitating smooth handling, and preventing curling. Understanding the importance of slip sheets can help printers improve the quality of their prints and ensure that the final products meet high standards. Next time you see a beautifully printed document, take a moment to appreciate the role that slip sheets play in making it look perfect.

Do you have any more questions about slip sheets in printing? Feel free to ask in the comments below!

Slip Sheet Demo

Frequently Asked Questions

What is a slip sheet in printing?

A slip sheet in printing is a blank sheet of paper or cardstock used between layers of printed materials to provide protection and stability during the printing and transportation process.

How is a slip sheet beneficial in printing?

A slip sheet helps prevent smudging, offsetting, or any damage to the printed materials. It also facilitates smooth handling and stacking of the printed items.

When should slip sheets be used in printing?

Slip sheets should be used when printing multiple items, especially when they need to be stacked or transported, to avoid any potential mishaps or quality issues.

Are slip sheets reusable in the printing process?

While slip sheets can be reused depending on their condition, it is recommended to use new slip sheets for each printing job to ensure optimal protection and quality of the printed materials.

Final Thoughts

In conclusion, a slip sheet in printing serves as a blank, protective sheet placed between printed materials to prevent offsetting and damage. It is crucial for maintaining quality in printing processes, particularly when handling sensitive or freshly printed materials. Understanding what a slip sheet is and its purpose can help ensure smooth printing operations and minimize errors. A slip sheet in printing is a simple yet essential tool for achieving professional and flawless print results.